An innovative approach to product development and optimization, how do you tackle it? We recently visited our forward-thinking and distinctive client, BPO, who excels in this field. BPO is renowned for its advanced approaches to product development and optimization. What is their story and what has made them so successful? We delved deeper to find out.

The story begins with a challenge familiar to many companies: how can they develop products that not only meet the highest standards of performance and quality but are also cost-effective and can be brought to market quickly? 35 years ago, BPO recognized that product development and optimization simulations provided a significant advantage in the process. Now, many years later, BPO still uses simulations to design and improve products.

“We know that we must keep up with the latest developments to stay relevant,” explained Michiel Wassenaar of BPO during our conversation. “Our current methods are well-proven, but we must always reflect to continue providing the best advice to our clients.”

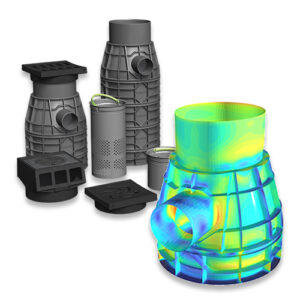

From the beginning, BPO embraced simulations as an integral part of their development process. By using advanced simulation technologies, they could create virtual models of their products and analyze different scenarios before even building a prototype. This allowed them to iterate faster and more efficiently, avoiding costly mistakes and shortening their time-to-market.

“Simulations give us an unprecedented insight into the behavior of our products under various conditions,” says Michiel Wassenaar. “This enables us to make much better decisions during the design process and ensure that our products meet the highest standards.”

However, the use of simulations went beyond merely improving the performance and quality of their products. BPO soon discovered that simulations were also a valuable tool in their pursuit of sustainability. By integrating simulations into their design and advisory processes, they could optimize materials and processes, reduce waste, and embrace a more circular approach to product development.

“Sustainability is important to us at BPO,” emphasized Michiel Wassenaar. “Using simulations allowed us to reduce our environmental impact and contribute to a more sustainable future.“

BPO has a history of 35 years in simulating products. Around the year 2000, they switched to Marc Mentat, which has been their foundation for simulations for 25 years, enabling them to provide advice to their clients. Later, they added MSC Apex as a preprocessor to their workflow, saving them significant time and considerably accelerating their workflow compared to alternatives. Some time ago, they sat down with In Summa again and expanded their package with many more software capabilities. This allows them to simulate products even better and more specifically for their clients. An example of this is Digimat, which enables simulations of products with glass fiber-reinforced materials to be carried out even better.

The story of BPO shows how innovation and technology can go hand in hand to help companies achieve their goals. By being one of the first to simulate plastic crates and embrace simulations, BPO was able not only to improve their products but also to strengthen their competitive position and contribute to a better world. It is an inspiring example of how creativity and perseverance can lead to real change.