Besides trends, there have also been many challenges in 2023. Keith Perrin, Director Design and Engineering at Hexagon Manufacturing Intelligence, mentions: “From where I’ve been sitting it’s been clear that Engineers’, biggest challenges are to do with the availability, flow and usefulness of information they need in order to work on challenges together and get things done.”. Again, the surge in data and every-increasing availability of information, to the point where it can overload, forms challenges that are not unique to engineering or the CAE-community. But in a design-cycle having the right data at the right time, is crucial. The wrong info at the wrong timing, has impact on more than just engineering – the whole production process and potentially the whole company.

For example, using an incorrect material property or sharing an older instead of newer file can not only have consequences for the simulations, but the whole design and even go-to-market process later on if things delay. Investing time and money in proper data management and collaboration tools is not the most exciting, but could very well be the most important decision to take the upcoming year. Keith: “At a more personal note, I am delighted to be seeing more and more meaningful discussions about how we work together, collaborate and iterate on the tough challenges we face. To date this has been the area of complex PLM discussions. With more modern notions of collaboration we’re really starting to see some meaningful change in the tools we have to enable this.”

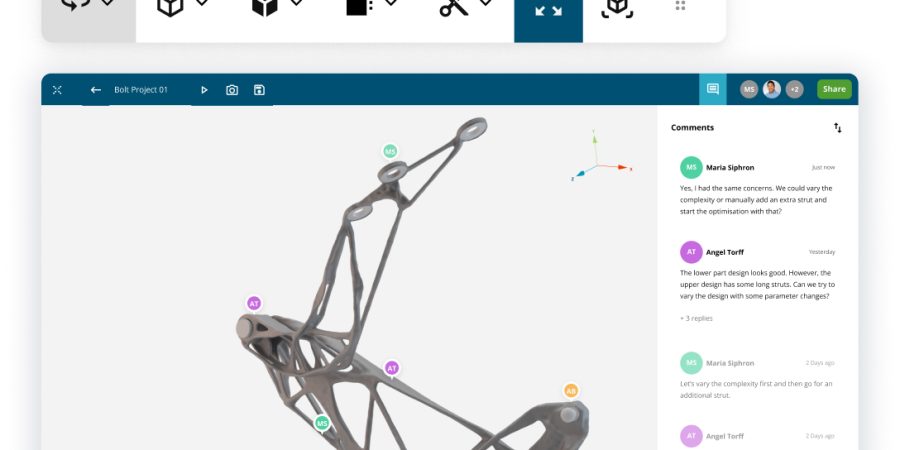

Platforms like Nexus, which was launched at the beginning of the year, are such tools Keith is referring to: “With technologies like Nexus, I think we’re positioning well to support more fluid collaboration, across our customer’s tools, teams and environments.”. For many at Hexagon, the launch of this platform and the potential this poses for the future, was for sure a highlight. A few of our customers in Benelux have been actively involved in testing it out already. Especially material suppliers and material engineers are getting the first benefits of Materials Connect – A cloud-native visualization and data management solution that provides seamless access to material data, and Materials Enrich – combining material modeling and machine learning to efficiently enrich material data.

For next year we look forward to many more similar apps, solutions and successes coming from this platfrom of possibilities. We hope we can collaborate with you on many projects, and we can facilitate the collaboration within your work that you need to succeed.